Together we can bring life and dignity back to thousands of people suffering around the world

THE PROSTHETICS INDUSTRY HAS NOT SOLVED SIGNIFICANT CHALLENGES

44%

of patients do not use their prostheses

- 01 It is not possible to provide bionic prostheses to developing countries at an affordable price and conditions of receipt

- 02 Does not respond quickly to emergency situations, such as wars, conflicts, disasters, where it is necessary

- 03 In the presence of powerful modern technologies, limits itself to outdated slow models of prosthesis manufacturing and provision

OUR PURPOSE

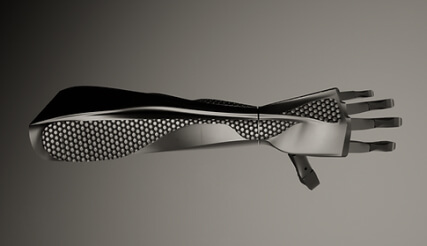

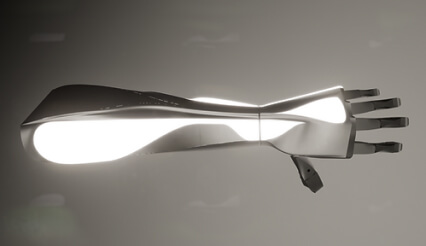

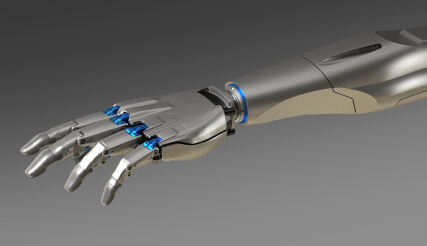

Prostheses with individual high-end design of a stylish device that you do not need to be ashamed or hide

Focus on long-term comfortable use, continuous improvement of control algorithms and functionality updates for long-term use

Flexible solution for both below elbow amputations and, what very few companies do, above elbow amputations. In addition, exoskeletons to replace lost fingers

Decentralized, modern manufacturing solutions that allow production directly where it is needed, at an optimized cost that is (many times) lower than other manufacturers' offers

A decentralized, rapidly deployable and scalable solution for patient assessment, scanning and care

OUR VISION

REIMAGINATION

Reimagine a prosthetic device as an AI chip that allows for automated manufacturing, local manufacturing near end users and does not require expensive support services.

AI BASEMENT

The heart of our AI vision is a self-directed deep learning chip, one that can be configured to the specific needs of the end user, albeit any part of the body, any sensors, any configuration and once configured is sent to the autonomous manufacturing pod and the same pods can print, create assemble and lights out test/calibrate the resultant prosthetic

INNOVATIVE MATERIALS

To achieve it we use new materials that can be 3D printed to overcome weight bearing limitations on current low cost 3D printed materials for prosthetics, printed ink based sensors that can be cost effectively integrated into a 3D print environment, and, most importantly, leverage the rapidly growing advances in embedded AI, particularly those that are emerging from military applications

TEAM

Volodymyr Bandura

Project Manager, Global Ambassador of Singularity University, technology expert and speaker

Steven

Van Fleet

Developer, project manager of new product development and production.

Khrystyna Hrynchuk

Project Manager